The primary trail surfacing is the basic building block of the greenway, and it is critical that it is well-designed and well-implemented.

The cross sections below were developed meet these demands while also provide a long-lasting trail that can hold up to maintenance and emergency vehicles. These cross sections should be considered minimum standards, additional thickness of materials or other special considerations may be required due to specific site conditions. Final detail design should be based on the site, specific engineering needs and the input of a geotechnical consultant. Proof-rolling should be performed in all areas to be paved to verify adequate sub-base. Sub-base should be remediated with rock. If areas are identified for remediation during proof-rolling, sub-base should be remediated with rock and Geo-grid should be placed over rock course before pavement base is installed.

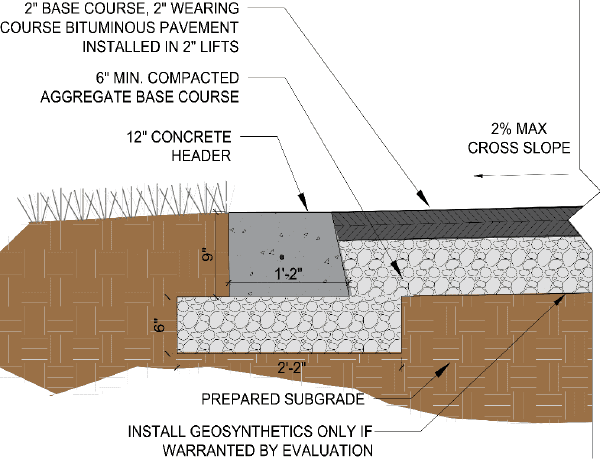

ASPHALT WITH CONCRETE HEADERS – PREFERRED MATERIAL

Asphalt with concrete headers has become the most common and recognizable GRG trail surfacing. The asphalt creates a smooth surface, recognizable as a transportation corridor. With this surfacing, the overall cross section width of the trail is increased, so that the path of travel remains 12’-0” wide with concrete headers outside of it.

PROS:

- Cost effective, smooth surface.

- Contained edges for increased longevity.

- Recognizable wayfinding (roadway like).

- Provides best contrast for striping.

- Concrete headers create a more accurate and higher quality final layout than asphalt alone.

CONS:

- Requires re-sealing and mill/overlay.

- Not as durable over time as concrete.

- Concrete headers add additional cost. Joint between asphalt and concrete often separates, leading to problems with weeds and cracking/ settling of asphalt. Regular resealing and life-cycle based, periodic milling and overlay of asphalt will mitigate this problem.

NOTES:

- 12’-0” wide asphalt trail with 1’-0” concrete headers at edges.

- Should be used as primary trail material for all applications if possible.

- Cross slope of 1% – 2% required.

- Design curbs and raised concrete surfaces to avoid trip hazards. Where raised curbs or edges intersect and form corners, apply a 1′ minimum radius. Transitions from raised to flush curbs shall be gradual.“

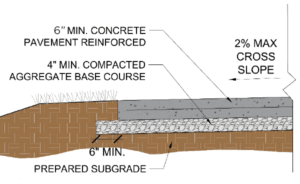

CONCRETE – PREFERRED ALTERNATIVE MATERIAL

Concrete is an extremely durable and long-lasting trail surfacing material. However, in the context of many greenways, it can easily be mistaken as an extra-wide sidewalk. Concrete should be installed to minimize jointing, as jointing can make for an uncomfortable travel surface.

PROS:

- Longer lasting material.

- Can be a lower cost than using concrete headers

- Can be installed later in the season than asphalt.

CONS:

Typically higher cost than asphalt.

- Expansion and control joints create a bumpy trail surface not desirable to users.

- Has a sidewalk appearance, and is less recognizable as a multi-use trail.

- Concrete has higher quality layout and tolerances for finished grading.

NOTES:

- Fiber reinforcement to be specified at a dosage rate per manufacturer recommendation and verified by the engineer. Note the need for surface finishing when coordinating with manufacturer.

- Saw-cut control joints are preferred.

- Expansion joints are to be placed at regular intervals. Joints to be sealed.

- 12’-0” wide broom finished concrete trail.

- No control or expansion joints are to be placed parallel to the path of travel except where needed at intersections.

- Concrete should be reserved for ramps, aprons, approaches, and trail amenity areas due to cost considerations or special site requirements.

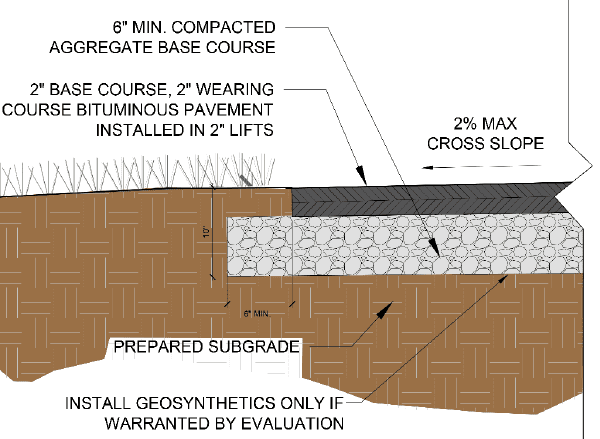

ASPHALT WITHOUT CONCRETE HEADERS – ALTERNATIVE

Standard asphalt surfacing has the benefits of the preferred asphalt with header trail, without the additional cross section width or cost of the installation of headers.

PROS:

- Recognizable (roadway like).

- Provides good contrast for striping.

CONS:

- Unconstrained edge may contribute to failure at edges.

- Layout is less accurate than with concrete and may be dependent upon quality of workmanship alone.

NOTES:

- 12’-0” wide asphalt trail without edge constraint.

- May be used in areas where space is limited.

- Standard asphalt surfacing has the benefits of the preferred asphalt with header trail, without the additional cross section width or cost of the installation of headers.

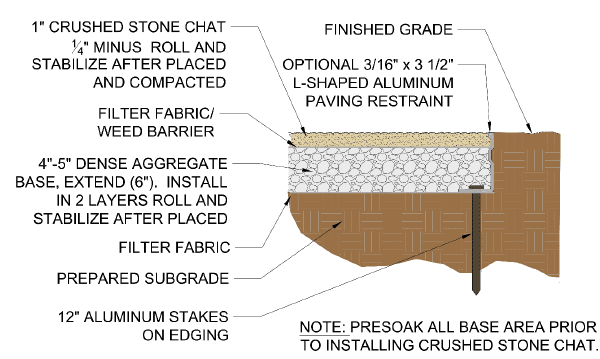

CHAT – ALTERNATIVE MATERIAL

Limestone chat is a cost effective alternative to concrete in areas that are relatively flat. Chat compacts to a hard trail surface that can also give, somewhat, and is a great option for trails that will be frequently used by runners. It does require more regular maintenance than concrete, particularly to address low spots that may form over time.

PROS:

- More cost effective than concrete.

- Lower impact than concrete.

- Desirable for runners / walkers.

CONS:

- Requires regular re-application of material.

- Potential of material washing out during storm events.

- Cannot be used on slopes greater than 5%.

NOTES:

- Only to be used where standing water or saturated soils are not a concern.

- Aluminum paving edge restraint is optional where a cleaner, more contained edge is required or desired.