SITE SUPERVISION

- A supervisor/ foreman shall be on site at all times while work is being installed. Change of supervisor/ foreman during project implementation is discouraged.

TESTING

TESTING

Testing of materials and installation quality should be an on-going effort throughout the duration of construction and should be documented. Drawings and specifications should clearly define the critical tests and milestones during the process based on the following criteria.

Compaction testing

- GRG shall have independent geotechnical engineer evaluate compaction during construction to ensure that compaction for pavement and load-bearing structures meets the designed specifications and details.

- For trail pavements:

- Contractor should verify and document that proof-roll has been carried out on all sub-base prior to placement of base course.

- Base course must be verified to meet installation tolerances and compaction requirements prior to placement of finish pavement.

- Testing should be performed every 300’ along the entire length of trail surfacing or where significant changes in site conditions merit additional testing, such as in wet areas and near significant site features.

- For retaining walls and bridge abutments:

- Back-fill should be installed in lifts per detail. Each lift should be tested at 50’ intervals along the length of wall to verify adequate compaction.

- For load bearing structures (foundations):

- Testing should be conducted as indicated on engineer’s drawings.

Materials testing

Materials testing

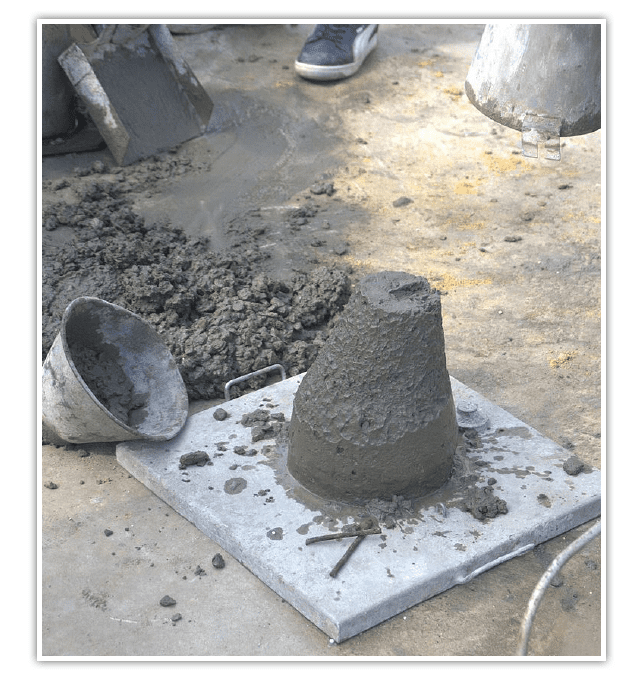

- Material samples and testing records for pavements and structural concrete should be collected and retained for GRG’s records. Samples and records should be collected for each batch of material. Materials samples to be held by GRG for at least 5 years following completion of work.

Soils testing/ amendments

- Test each planting soil area. Large native meadow areas and turf areas should be spot tested. Test results should be submitted to client and designer. Areas damaged during construction, with results varying significantly from pre-construction testing will need to be rectified by contractor at his or her cost.

- Design team to provide soils plan and specifications for soils mixes, amendments, and/ or preparations, based on pre-construction testing results.

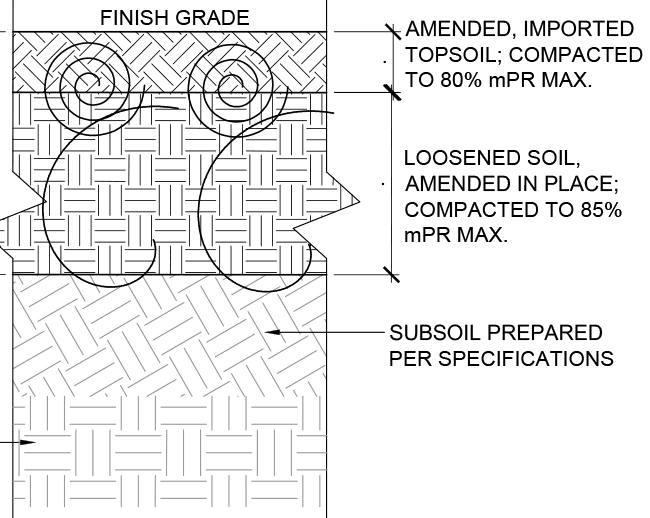

- Include detail drawings for design soil profiles.

SWPPP implementation inspector

- SWPPP implementation measures should be inspected weekly and after significant rainfall events as defined in the SWPPP plan.