Specialty pavements are important elements used to celebrate a specific node along the greenway, and can be used to brand/ identify a particular greenway.

As special materials, specialty pavements should be used strategically and sparingly along the length of the greenway. Specialty pavements should be used only in non-traffic areas. Do not use in drive lanes or roadways. The following details are for reference only, and final detail design should be based on the site, specific engineering needs and the input of a geotechnical consultant. Proof-rolling should be performed in all areas to be paved to verify adequate sub-base. Sub-base should be remediated with rock. Geo-grid should be placed over rock course before pavement base is installed. Some paving patterns, like the example to the left on River Des Peres Greenway, can have a disorienting or dizzying effect on trail users. Rectilinear patterns are preferred for areas within the primary trail route.

Concrete pavers and integral colored concrete are just two examples of specialty pavement that can be used at various points along a trail. Wavy or disorienting patterns, such as the image on the left, can have unwanted effects on some trail users and should be avoided.

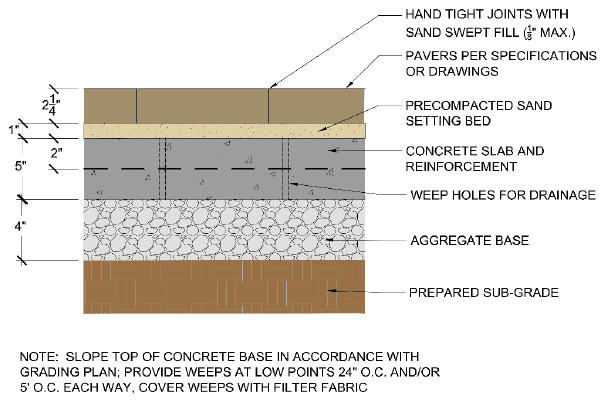

PAVERS ON CONCRETE BASE – PREFERRED MATERIAL

Concrete and brick pavers provide a myriad of options to create a unique and identifiable statement along a greenway. The flexibility of pavers also allow for the embedment of integrated branding elements directly into the paving surface. Pavers, however, have their own unique maintenance challenges particularly over several years. If pavers are to be used, they should always be placed on a concrete base.

PROS:

PROS:

- Pavers can be easily replaced if damaged.

- Opportunities for branding/ interest.

- Non-fading colors

CONS:

- Resetting may be required if settling occurs.

- Weed control can be challenging. It is critical that joints are well sealed with polymeric joint lock sand.

NOTES:

- All pavers, except in permeable applications, should be installed on a concrete base. Do not mortar.

- Pavers should be of a high compressive strength, 7000 psi or greater.

- Concrete base should have adequate drainage and weep holes.

- Edge restraints are required in this application. Concrete base must extend beyond edge of pavers to allow anchoring point for edge restraint.

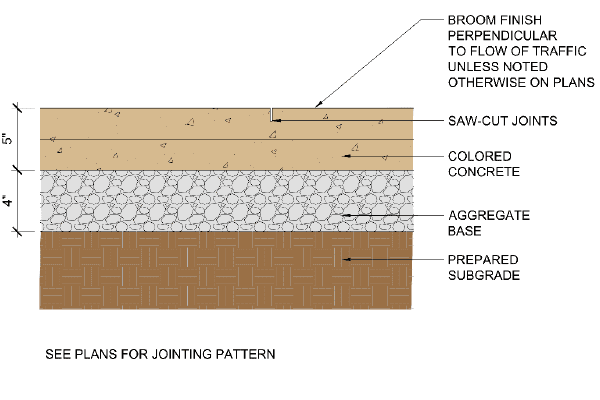

COLORED CONCRETE – ALTERNATE MATERIAL

COLORED CONCRETE – ALTERNATE MATERIAL

Like pavers, colored concrete can create interesting design and branding opportunities. It is critical that colored concrete be used in areas that will not receive heaving salting, for best results.

PROS:

- Can be less costly than concrete pavers.

- Opportunities for branding/ interest.

- Limited weed pressure.

CONS:

- If damaged, repairs are difficult to match.

- Can be a challenge to install.

- Color fades over time.

NOTES:

- Color is to be integral to concrete mixture.

- Use in high visibility/ high profile areas.

- Saw cut joints should be used in path-of-travel areas.

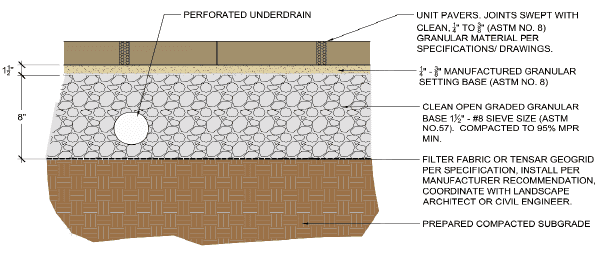

PERMEABLE PAVERS – ALTERNATE MATERIAL

PERMEABLE PAVERS – ALTERNATE MATERIAL

Permeable pavers are important tools in the stormwater management toolbox. In addition, the flexibility of this type of paver system provides many opportunities for branding and design creativity. Permeable pavers should be set on slopes of less than 2 to 5% for best functionality.

PROS:

- Aids in mitigating stormwater runoff.

- Visible green infrastructure for public recognition.

- Easily replaced if removed for utility work.

CONS:

- More costly than traditional pavers.

- Gravel setting base means that, over time, pavers may settle in areas with frequent travel. Permeable pavers should be used in areas with limited vehicular turning movements.

- Permeable pavers may require more frequent maintenance than traditional pavement surfaces.

NOTES:

- Permeable pavers should be contained by a concrete curb, concrete header, or adjacent concrete surfaces.

- Utilize in parking areas, pedestrian gathering zones and locations with travel speeds below 25 mph and with minimal turns. Use in vehicular travel lanes should be avoided as vehicle movements cause settling and increased wear.

- Pavers should be of appropriate thickness and strength to withstand expecting loading conditions. At a minimum, pavers should withstand loading from typical maintenance vehicles.

- Trees can exacerbate maintenance issues on permeable pavements, requiring additional vacuuming for performance. Tree species with larger leaves and limited fruiting should be selected for placement near permeable pavers.

It is important to inspect permeable paver installations after major storm events to make sure stormwater drains properly.