Detectable warning surfaces provide an additional level of safety and security for those who are visually impaired.

They alert users to a change in elevation or crossing. The use of truncated dome tactile warning surfaces is required under the Americans with Disabilities Act.

- New construction to be cast into concrete.

- Surface applied materials may be used in retrofit applications.

- Material must be durable and ADA compliant.

- Material color for truncated domes must visually contrast with adjacent surfaces.

- Surface must be non-skid.

- Truncated domes used to warn pedestrians and bikers that they are entering a hazardous vehicular area.

- Detectable Warning Surfaces shall contrast visually with adjacent walking surfaces either light-on-dark, or dark-on-light. (ADAAG)

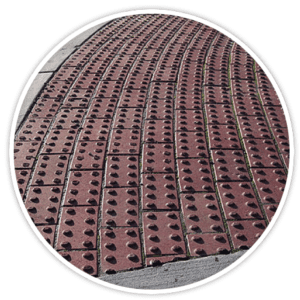

CAST IRON TACTILE – PREFERRED MATERIAL

CAST IRON TACTILE – PREFERRED MATERIAL

Cast iron tactile surfaces can be installed in the same manner as more-common composition tile, but is extremely long lasting and completely recyclable. Cast-iron meets standards for contrasting color when placed in concrete.

BEST USE AREAS:

At any intersection. Should be preferred option for primary trail.

PROS:

Extremely durable. Can be installed into wet concrete, like composition tile.

CONS:

Radius applications may require custom castings.

PRE-CAST CONCRETE PAVER – SPECIALTY PAVEMENT AREAS

PRE-CAST CONCRETE PAVER – SPECIALTY PAVEMENT AREAS

In areas featuring other specialty pavement, pre-cast concrete pavers are a good choice for curb ramps. Pavers should be installed on a concrete base (SEE Pavers). Truncated dome pavers are available in a variety of sizes, but traditional brick pavers (4×8 or 6×12) provide the greatest flexibility for radius applications.

BEST USE AREAS:

At intersections where greenway nodes call for specialty pavement, especially in nodes with pavers.

PROS:

Aesthetics. Easily installed in radius.

CONS:

Require special base if used in concrete areas.

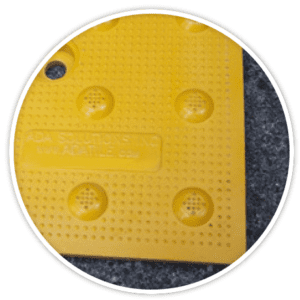

EMBEDDED TACTILE WARNING TILE

EMBEDDED TACTILE WARNING TILE

These are the most common truncated dome surfaces used in the public realm. These are typically made of polyester and fiberglass composites, and are embedded directly into wet concrete or installed after concrete is cured. Replaceable modules are preferred, as high traffic at intersections and sunlight can degrade the material over time.

BEST USE AREAS:

Considered the default for all regional traffic authorities. Can be used at any intersection, but should be considered an inferior option.

PROS:

Low-cost. Radius sections available.

CONS:

Can be damaged easily over time. Do not stay well-attached to surface and need to be re-fastened. Not long-lasting.