Roadway and service drive pavements need to be robust to support the weight and impacts of regular vehicular travel.

In general, pavements that are intended for through traffic, like driveways and parking lot aisles should be designed based on these cross sections. These cross sections should be considered minimum standards, and additional thickness of materials or other special considerations may be required due to specific site conditions. The following details are for reference only, and final detail design should be based on the site, specific engineering needs and the input of a geotechnical consultant. Proof-rolling should be performed in all areas to be paved to verify adequate sub-base. Sub-base should be remediated with rock. Geo-grid should be placed over rock course before pavement base is installed.

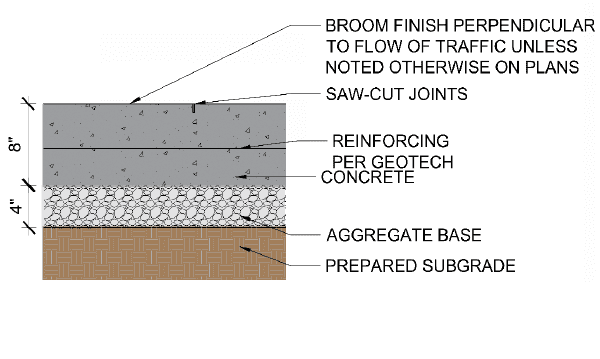

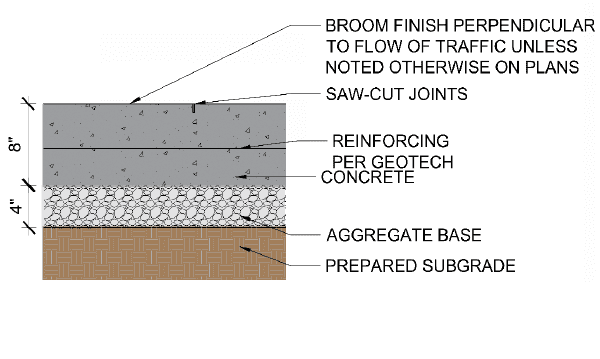

CONCRETE – PREFERRED MATERIAL

CONCRETE – PREFERRED MATERIAL

Concrete is robust and long-lasting, and is a preferred material for roadways, service drives, and parking lot aisles. Though more expensive than asphalt, concrete is an especially good option in areas where heavy maintenance or utility vehicles will frequently pass.

PROS:

- Longest lasting option.

CONS:

- Cost.

- De-icing salt can pose a significant problem especially when joint sealants are not maintained.

NOTES:

- To be used for driveways, parking lot drive lanes, and service access/areas.

- Include 4” min. compacted aggregate base course below concrete road surface.

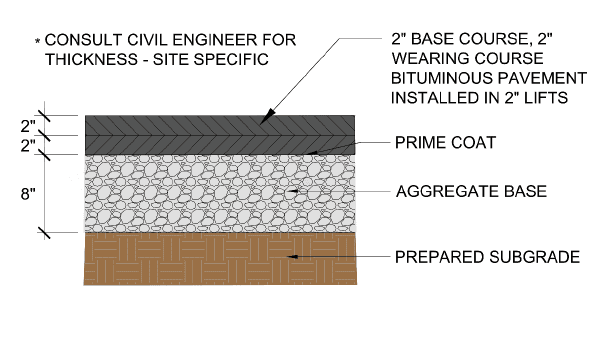

ASPHALT – ALTERNATIVE MATERIAL

ASPHALT – ALTERNATIVE MATERIAL

Asphalt is a common roadway material for good reason. Its low installation cost and resistance to cracking make it a good alternative for vehicular pavements. Proper installation of the base aggregate is critical to its longevity.

PROS:

- More cost effective than concrete.

CONS:

- More maintenance than concrete; requires sealing and eventual mill/overlay.

NOTES:

- To be used for driveways, and service access/areas.

- Include 8” min. compacted aggregate base course below asphalt surfacing.

LIMESTONE AGGREGATE – FOR NATURAL AND LOW-IMPACT AREAS

LIMESTONE AGGREGATE – FOR NATURAL AND LOW-IMPACT AREAS

For areas of lower traffic or where a low-cost, low-impact solution is desired, limestone aggregate is a good paving alternative. However, it does require more regular maintenance than other alternatives.

PROS:

- Low cost option.

- Good for lower impact areas, where more formal paving is not necessary.

CONS:

- Requires regular replacement and regrading of material.

- Potential of material washing out during storm events.

NOTES:

- To be used in low usage trail access areas.

- Slopes should not exceed 20:1.