Construction mock-ups are to be used to verify a quality product prior to significant work being performed by the contractor.

They can be used to review unique details or materials to ensure they meet the desired design criteria and intent.

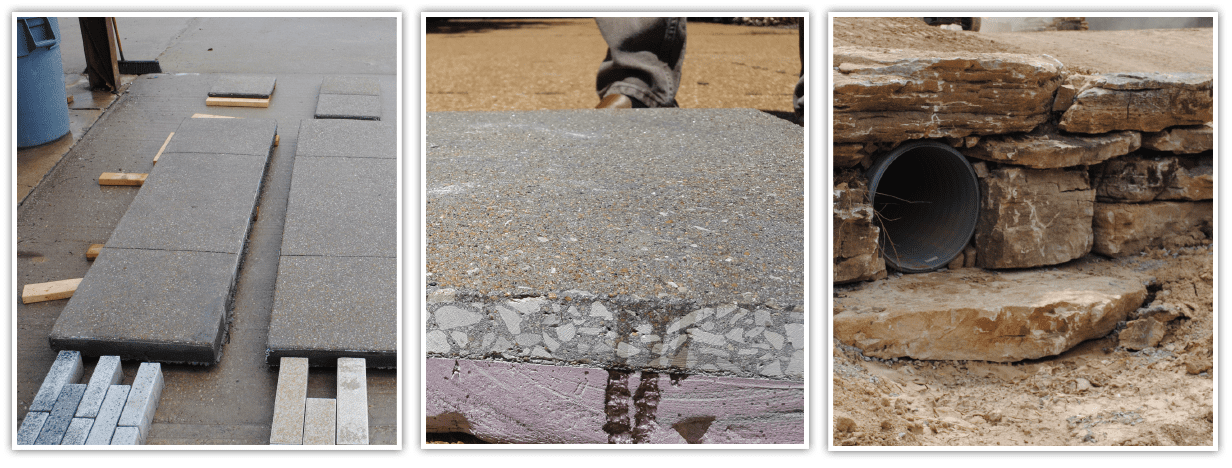

Trail mock-up

- A 30’-0” long segment of trail should be constructed including adjacent grading, coursing, headers, jointing, etc. A different length can be agreed upon with contractor and client as needed.

- The preferred location of the mock-up should be coordinated with contractor and GRG.

- This mock-up should be reviewed and tested for quality of installation:

- Base course installation and compaction.

- Consistency of implementation.

- Level trail surface without humps/ lumps.

- Graded correctly for cross slope.

- This mock-up can be included as a portion of the finished work, and will serve as a benchmark for all other work.

Walls

- Wall mock-up should include an end section of wall, if applicable, to verify end cap or return. Mock-ups should contain the entire wall assembly from footing and back of wall drainage to cladding and wall caps.

- Can be included as part of the finished wall.

- For veneer/ brick/ solid masonry walls:

- Review for quality of jointing, mortar install, consistent coursing. Especially important for natural stone.

- Review mortar color.

- Verify the installation of back-of-wall drainage and tie-backs.

- For CMU/ Modular walls

- Verify consistency of coursing (level)

- Verify the installation of grade tie-backs.

Colored or specialty concrete or pavers

- A 4’x4’ mock-up representing finished quality to include edge, corner, and joint conditions.

- Can be included as finished product or be separate sample.

- Review color, finish, jointing quality, aggregate.

- Review consistency of implementation and correct grading/ cross slopes.

Tree installation

- May include representative installation of canopy, flowering and evergreen trees.

- Installation should be reviewed to ensure that installation is done per drawings and specifications.

- Soil percolation test.

- Review method of backfill and installation procedures.

- Review staking or guying of trees (if applicable).

Other specialty items

- Other mock-ups, as required, to ensure a quality finished product, mock-ups may be indicated by the designer and should be clearly identified in drawings or specifications. (Fencing, railings, lighting, custom furnishings.)